Integrating Scopes 1, 2 and 3 Emissions Visibility for a Sustainable Future

Imagine being able to understand your global business operations, not just from a financial bottom-line perspective, but also the environmental impact of key decisions. That’s the power of including sustainability factors into long-term capital planning and economic studies models. Doing so enables companies to gain a new kind of vision, an x-ray vision for sustainability, to reveal opportunities hidden within the intricate manufacturing and supply chain network of your global business.

Aligning Business Planning with Sustainability

Traditionally, businesses have approached sustainability as a separate initiative, often focusing on reporting past environmental impact. Some companies are now recognizing the need for a more proactive and integrated approach – one that embeds sustainability into the core of their business planning processes.

By considering sustainability metrics early in the long-term capital planning process, businesses can make more informed decisions about resource allocation, prioritize projects aligning with their sustainability goals, and enhance their long-term resilience.

Case Study: Albemarle Specialties Global Business Unit (GBU)

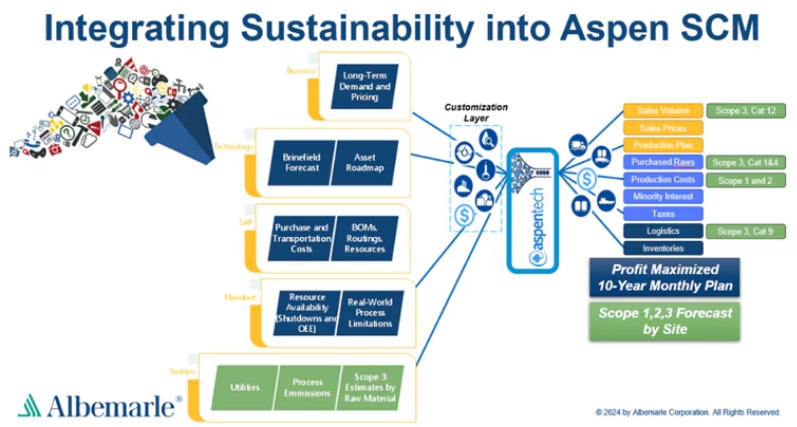

Kyle Schmidt, a process evaluator at Albemarle’s Specialties GBU, gave a presentation during AspenTech’s OPTIMIZE 24 user conference detailing how they incorporated sustainability factors and metrics into their AspenTech Supply Chain Planner™ optimization model.

They have used this powerful solution for several years in support of their long-term planning and economic evaluations to deliver bottom line benefits to the business. For example, the tool enabled them to run multiple scenarios where they found a combination of capital projects, related to complex integrated production units, that resulted in 15% less capital spend and a 5% increase in returns.

Making the Invisible, Visible: A Deeper Dive into Emissions

It was critical for Albemarle’s team to align their Supply Chain Planner model with the Greenhouse Gas Protocol Corporate Standard, a globally recognized framework for emissions reporting. This framework categorizes emissions into three scopes:

- Scope 1 encompasses direct emissions from sources owned or controlled by the company, such as on-site combustion and company vehicles.

- Scope 2 considers indirect emissions from purchased energy, including electricity and steam.

- Scope 3, which is often the most complex to measure, encompasses all other indirect emissions across the value chain, including those associated with purchased goods and services, transportation, and product end-of-life.

The process of integrating sustainability into their long-term planning optimization model wasn’t simply about adding a few new data points. It was about fundamentally changing how they viewed their operation. They used the example of brine, a key raw material in their operations, to shed more light on the matter. Traditionally, they viewed brine through a cost-per-unit lens. But when viewed through a sustainability lens, they started to see the energy required to move it, the steam needed to treat it, and the associated CO2 emissions. To accomplish this, they made several key modifications to the data ingested by their planning optimization model.

- Detailed utilities data: Instead of treating utilities as a background cost, they meticulously tracked power consumption for each stage of the value chain. This granular approach revealed Scope 2 emissions, the indirect emissions from purchased energy.

- Process emissions data: CO2 emissions from steam production and other processes were modeled as materials – tangible inputs and outputs. This allowed them to keep track of Scope 1 emissions with a great degree of accuracy and granularity.

- Scope 3 factors: Recognizing the significance contributions of their supply chain, Albemarle integrated Scope 3 carbon intensities for all purchased raw materials.

Through these efforts, the company’s long-term planning model now generates a dual output. The existing profit-maximized 10-year monthly plan, in addition to a site-specific and total business forecast of greenhouse gas emissions over the same period.

Source: AspenTech Optimize 2024 conference, “Forecasting Sustainability Metrics and Long-Term CAPEX Planning”, Kyle Schmidt, Albemarle Specialties

Reaping the Rewards

The integration of sustainability metrics has yielded tangible benefits for them.

- Enhanced project evaluation: By considering both economic and environmental factors, they can now identify projects that deliver a double win. For example, a process intensification project not only made financial sense but also yielded an 11% reduction in water intensity and a 6% reduction in carbon intensity.

- Value chain optimization: The optimization model revealed opportunities for 16% site carbon intensity reduction via vertical integration, which decreases reliance on external suppliers and minimizes transportation related emissions.

- Data-driven decision making: The integration of scopes 1, 2 and 3 forecasts directly into their long-term 10-year financial model equips them with a more comprehensive understanding of the long-term impacts of their decisions.

Albemarle emphasized that this is an ongoing journey with some additional milestones in their line of sight.

One milestone is generating proxy Life Cycle Assessments (LCAs) at the product level, for all their products, further leveraging their long-term planning model. The goal is to provide customers with detailed carbon intensity data for individual products. This will enable them to further optimize their operations and meet the growing demand for transparency from their customers.

The other milestone is to bring their long-term planning model’s capabilities and use it for their tactical and medium-term Sales and Operations Planning (S&OP) processes. This will ensure that sustainability considerations will be factored into all levels of planning decision-making. This will help them make decisions in response to short-term fluctuations in demand or resource availability, while staying aligned with their long-term planning sustainability goals.

Looking Ahead: Towards a Sustainable Future

Albemarle Specialties’ journey provides a compelling example of how companies can and should evolve beyond traditional, economically driven planning optimization models towards a more holistic and sustainable future. Their work serves as a call to action for all companies to embrace a new era of business planning. One where environmental stewardship is not an afterthought, but a fundamental principle woven into the very fabric of their business processes and operations.

.png?la=ja&h=415&w=675&hash=7EEEF762FF1B5BAAC3E121B29611791C)

Leave A Comment